Welcome to Vista 3D Technology Co., Ltd.!

Mobile

Application cases

From:惟景三维 Author:Vision3D

122023.10

On-line Automated Inspection System for Cast Steel Wheels

The modernization and increased load capacity of railways have imposed higher safety requirements on high-speed train transportation. As a critical component, the precision of train wheels directly affects the safety and comfort of train operations.

Traditional manual inspections rely on tools such as height gauges and calipers for line marking inspection. However, this method suffers from low accuracy,poor efficiency, and slow speed, unsatisfying the demands of large-batch inspections.

Solutions:

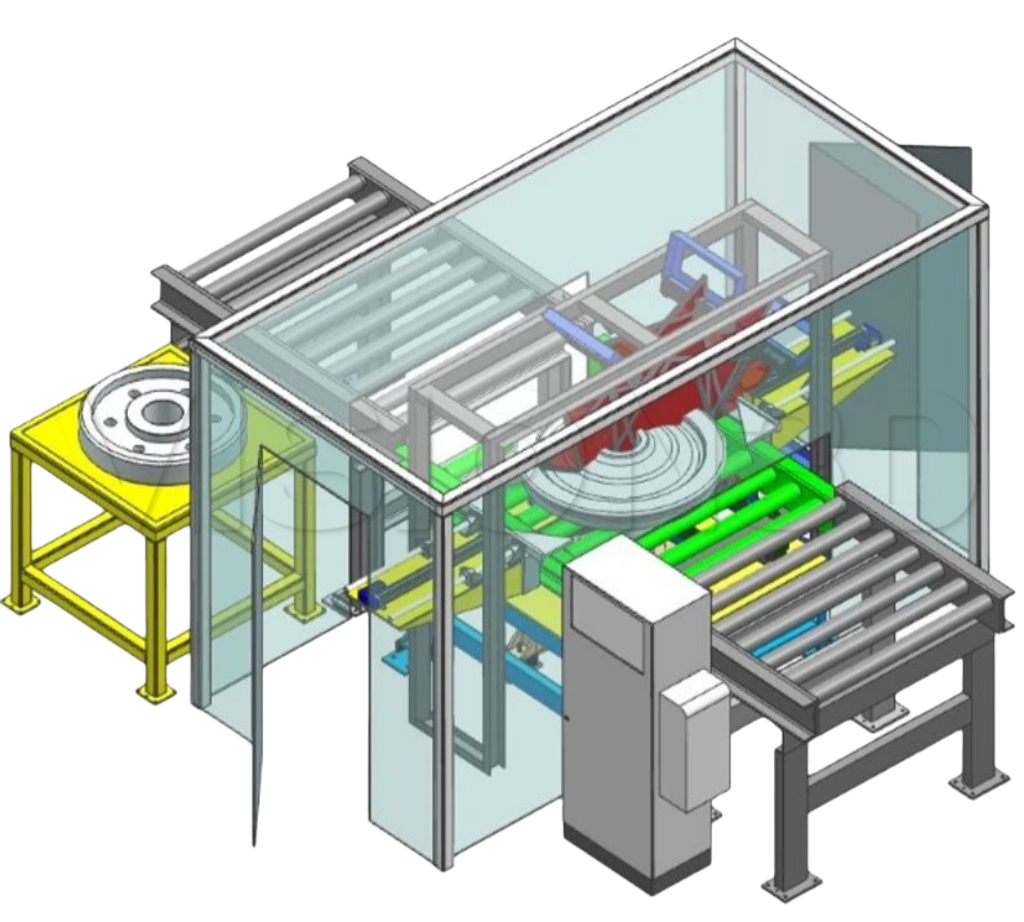

To address the above issues, Vision 3D has developed an on-line automated inspection system for cast steel wheels. This system comprises three major modules: image recognition, dimension measurement, and data management.It can recognize wheel steel stamp codes, capture 3D data with automatically analysis and inspection,then complete storage and classification of production information and scanned data.

01 Detection Process

The wheels to be inspected are conveyed to the inspection/testing station, where an image recognition system extracts and records the steel stamp codes on the wheels. Subsequently, the wheels are fixed on a turntable, and in coordination with a line laser inspection system, to fulfil 3D measurements. The system then transmits data such as wheel identification, inspection data, and analysis results to the management system.

02 Data Report

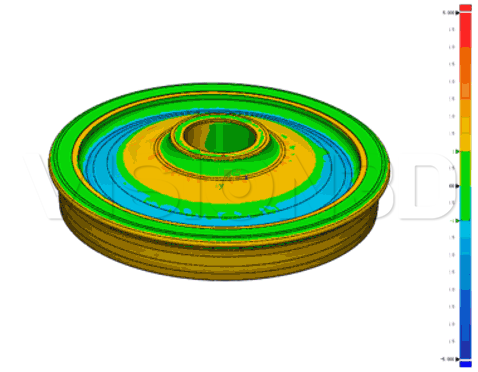

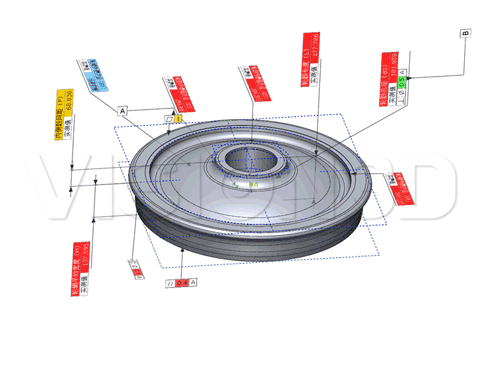

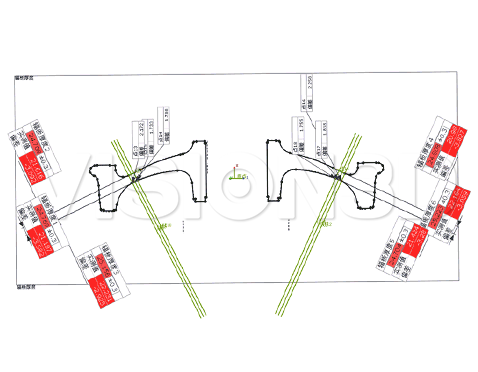

Each individual wheel collects key dimensional data, including rolling circle diameter, inner hub-to-rim distance, rim width, length, outer diameter, aperture, and rim profile. The system automatically compares and analyzes the collected data with the original CAD model, generating customized inspection reports.

Partial Data Report of Key Dimension

The online automated inspection system for cast steel wheels offers high precision and fast measurement speed without any manual intervention. It can complete the inspection of 1.5 wheel sizes per minute, providing greater economic benefits to enterprises.

Last:Application cases

Next:Application cases

-

Pre-sales:sales@vision3d.cnAfter-sales:aftersales@vision3d.cn

-

Pre-sales: 189 7166 9261After-sales:189 7166 8135

-

Consultation