Welcome to Vista 3D Technology Co., Ltd.!

Mobile

Application cases

From:惟景三维 Author:Vision3D

222023.09

Automated 3D Measurement of Train Coupler Cushioning Device

Project Background:

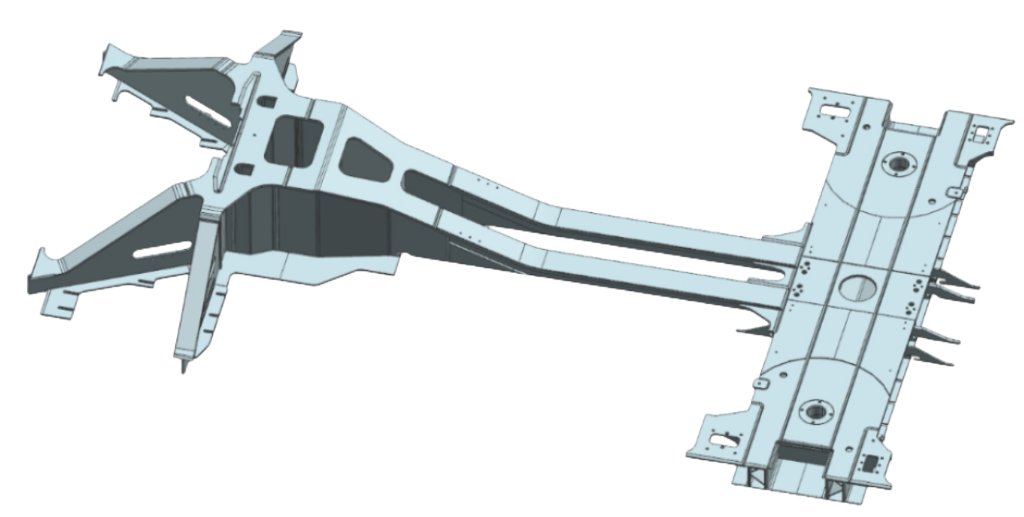

The train coupler buffer is a complex key stressed component with a complicated structure, comprising a buffer beam, bolster beam, and a traction beam/ draw beam. After manufacturing, more than 20 dimensions and positional tolerances/geometric tolerances of the coupler buffer need to be inspected. Currently, manual inspection methods are commonly used, resulting in low efficiency and poor accuracy./ inefficiency and imprecision.

Inspection Object:Train coupler buffer, with a total length of about 4 m and a width of about 2.6 m.

Technical Requirements:Inspection time ≤ 30 minutes, accuracy requirement ≤ 0.1mm.

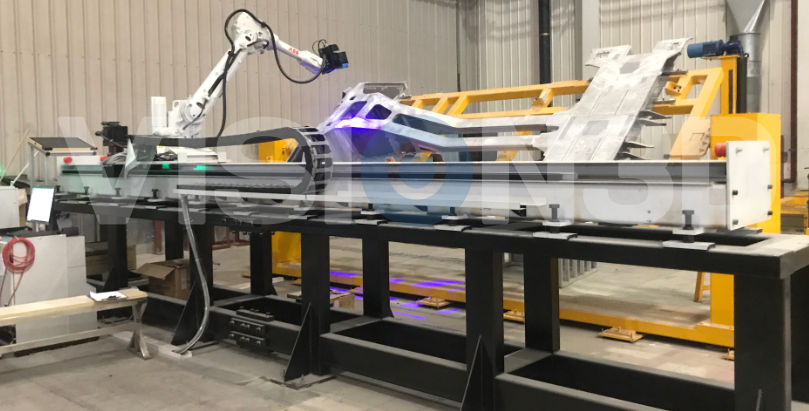

Measurement Equipment:AutoScan™ 5000.

Measurement Process:Measurements are automatically conducted based on a pre-planned measurement path, without the need for markers.The entire process of data measurement and processing is fully automated.

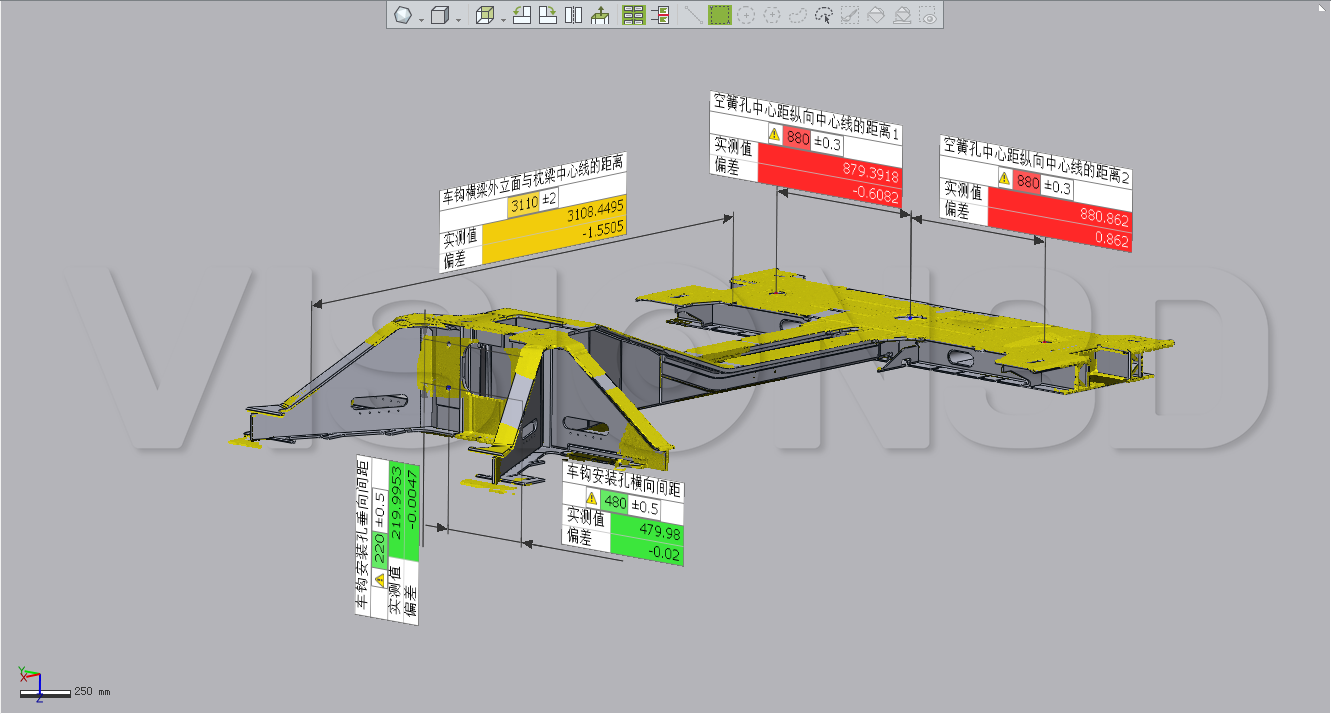

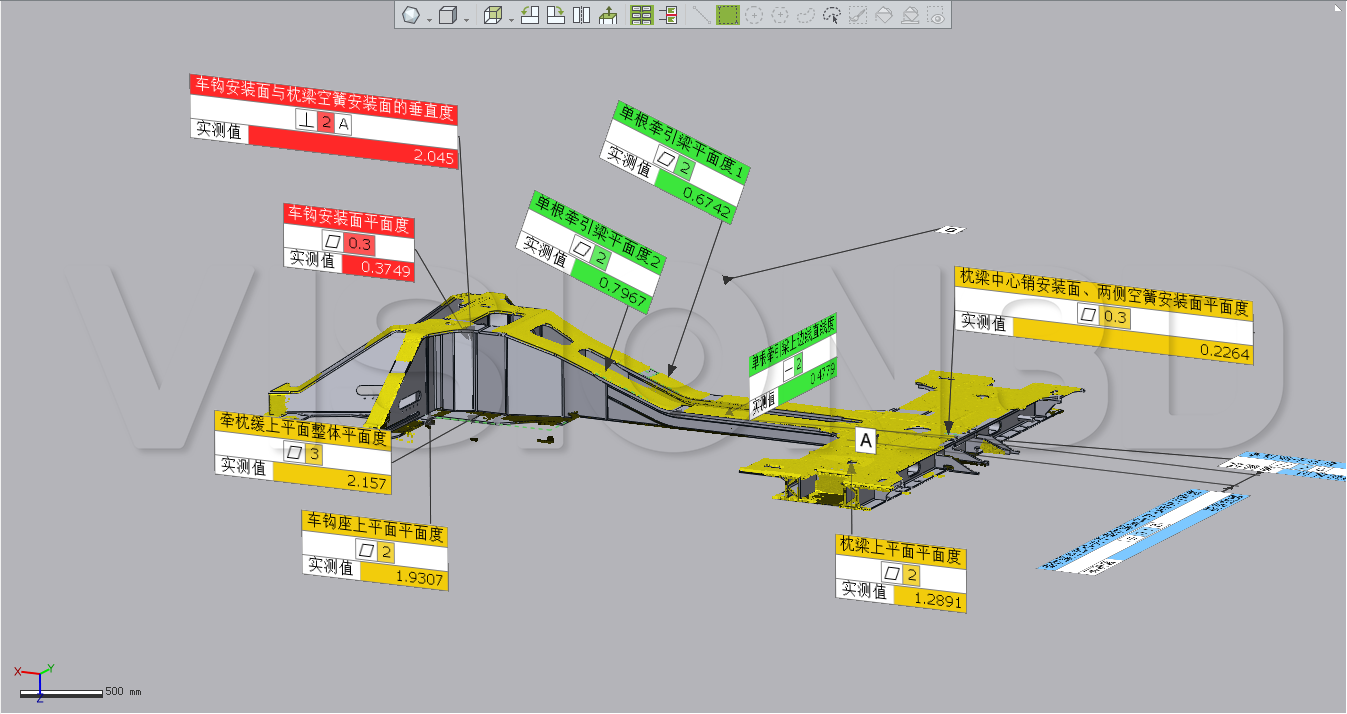

3D Inspection of Train Coupler Buffer

Partial Data Inspection Report

Case Summary:In this case, the AutoScan™ 5000 measurement system was utilized, which consists of a measurement probe, robot arm, linear guide, and precision turntable. The entire measurement process took 28 minutes, and the overall measurement accuracy surpassed 0.1mm.

Last:Application cases

Next:

-

Pre-sales:sales@vision3d.cnAfter-sales:aftersales@vision3d.cn

-

Pre-sales: 189 7166 9261After-sales:189 7166 8135

-

Consultation