Welcome to Vista 3D Technology Co., Ltd.!

Mobile

Solutions

From:惟景三维 Author:Vision3D

232023.09

Automated 3D Inspection and Precise Marking of Complex Aircraft Castings

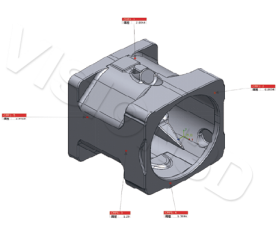

Castings are widely applied in aerospace, automotive, marine, and construction machinery industries. For example, for the wax models and castings of titanium alloy engine casings and aircraft fuselage, which have large volumes and complex shapes, ensuring casting precision is particularly important for improving manufacturing efficiency and guaranteeing product quality.

Sufficient machining allowance is an important criterion for evaluating whether a casting meets the requirements of the machining process. Before the machining process, castings like aircraft engine casings, tail frames, missile compartments and satellite housings are scanned by automated 3D measurement equipment to quickly obtain complete and accurate data. The precise results can determine whether the machining allowance of the castings meet the process requirements.

Due to the limitations of traditional methods, dimensional inspection of castings is time-consuming and labor-intensive. With its advantages of high precision, efficiency, and real-time capability, 3D measurement technology can facilitate the efficiency and accuracy of each stage in the casting process, from raw material inspection to subsequent machining operation.

Solutions:

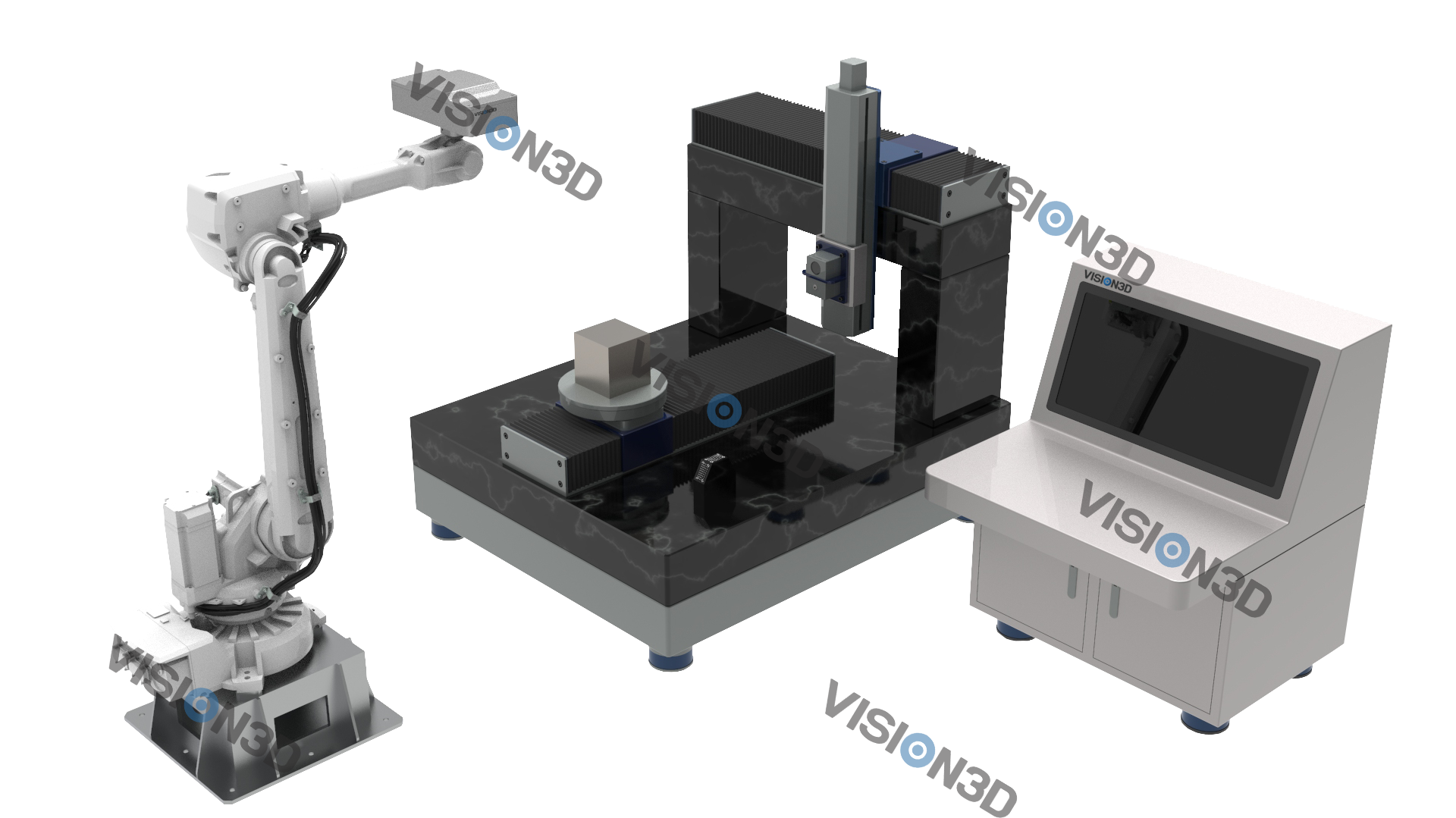

The Vision 3D’s AutoScan-D is a measuring system with allowance analysis and laser marking, specifically designed for complex castings. It enables fast measurement of machining allowances and quick positioning of machining references, guiding the laser marking device to mark the machining reference lines directly for subsequent precise machining.

01 Automated 3D Measurement:

The equipment can automatically scan the casting without any manual intervention. It captures 3D size data of the part and generates a complete model of the casting. During the measurement, the scanned data is displayed and analyzed in real-time, simultaneously, customized report is generated.

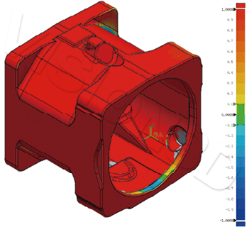

02 Comparative Analysis of Machining Allowances:

By comparing the 3D scanning data with the casting model, the machining allowances of each processing surface are automatically analyzed to determine if they meet the requirements of subsequent machining processes. In cases where the allowances are sufficient, the optimal reference state is identified to ensure precise and efficient machining.

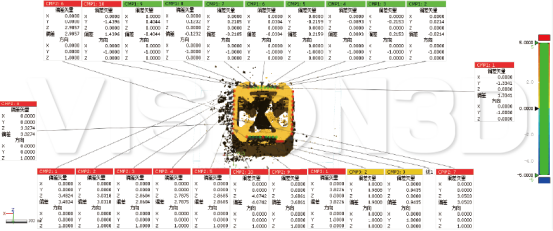

03 Automated Laser Marking:

In cases where the machining allowances meet the required standards/are qualified, the measurement data is automatically imported into the laser marking system and aligned with its coordinates. This process generates an optimal marking path. The system then utilizes this path to perform automated laser marking on the components.

Advantages of Vision 3D:

·Fully automated operation for both measurement and marking, significantly improving efficiency with a measurement and marking time of just a dozen minutes per individual casting;

·Without the reliance on manual expertise, it enables precise and comprehensive analysis of machining allowances, reducing machining waste and scrap rates;

·The inspection data is displayed in real-time and customized inspection reports are generated, providing data support for subsequent machining allowance determination and processing stages;

·The Vision 3D’s solution breaks through limitations imposed by complex industrial environments, allowing for enhanced inspection accuracy and efficiency in various application scenarios and spatial constraints.

-

Pre-sales:sales@vision3d.cnAfter-sales:aftersales@vision3d.cn

-

Pre-sales: 189 7166 9261After-sales:189 7166 8135

-

Consultation