Welcome to Vista 3D Technology Co., Ltd.!

Mobile

Solutions

From:惟景三维 Author:Vision3D

222023.09

Automated 3D Inspection for Aero-engine Turbine Blades

Aero-engine is recognized as one of the most technologically advanced and structurally complex industrial products in the world. It consists of more than ten thousands of components, the smallest details matter as they have an immediate impact on flight safety. Hence, the precision requirements for the manufacturing quality of aircraft engines is stringent.

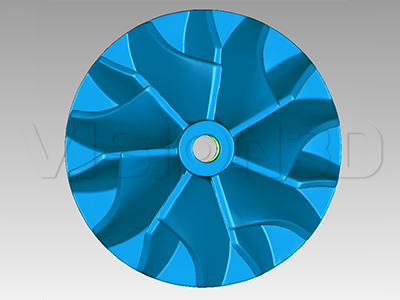

Turbine blades are relatively small in size, with a diameter of about 10cm. They are composed of complex curved surfaces and narrow 3D twisted flow channel spaces. The numerous dead corners and shadows result high difficulty in inspection, while traditional methods cannot meet the demands for large-scale, high-quality and efficient inspections during production.

The Vision3D’s AutoScan series of measuring devices adopt structured light and multi-viewpoint automatic stitching technology. They poses high precision and efficiency in measurement, providing various registration and positioning methods. The devices can quickly obtain 3D surface data of parts without the need for markering or powdering, and generate customized reports automatically, allowing for an effortless 3D batch inspection of turbine blades.

3D Point Cloud Data of Turbine Blades

Last:Solutions

Next:

-

Pre-sales:sales@vision3d.cnAfter-sales:aftersales@vision3d.cn

-

Pre-sales: 189 7166 9261After-sales:189 7166 8135

-

Consultation