Welcome to Vista 3D Technology Co., Ltd.!

Mobile

Solutions

From:惟景三维 Author:Vision3D

232023.09

More Accurate and Efficient | Optical Batch Inspection Solution for Aero-engine Blades

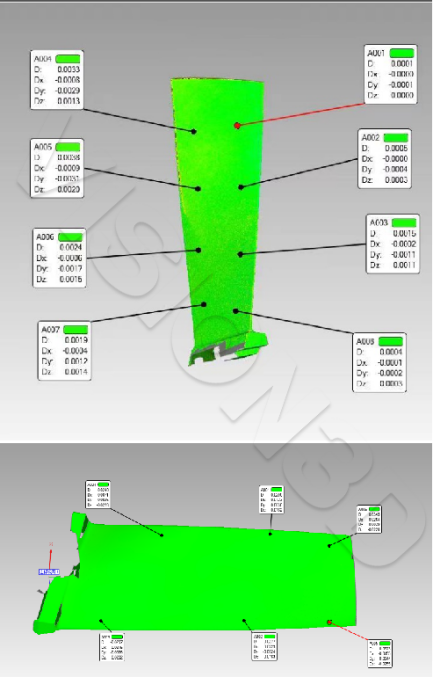

Small blades are a major type of aero-engine blades, characterized by complex airfoil profiles, extremely small leading/exhaust edge radii (with a minimum diameter less than 0.1mm), thin and twisted structures, numerous distinctive dimensions, large quantities, and high requirements for manufacturing and inspection accuracy.

Currently, the mainstream three-coordinate measurement methods have the following problems:

✦When measuring the leading/exhaust edge, the high curvature and small radius can result in errors in radius compensation, which seriously affects the measurement accuracy;

✦The inefficiency cannot meet the inspection demand for large quantities and various types of blades.

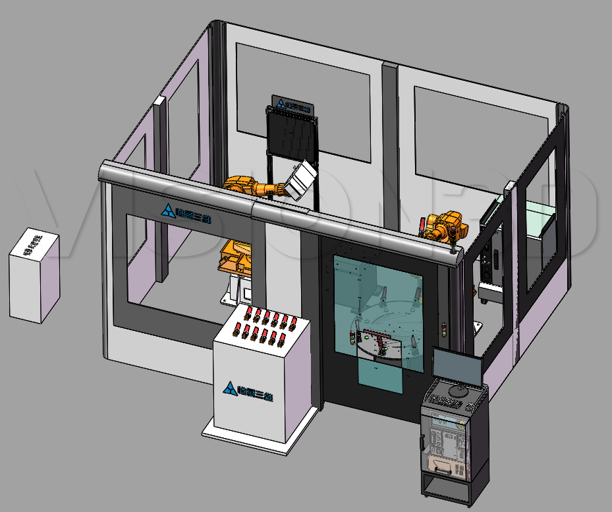

To improve the accuracy and efficiency, Vision 3D has developed a system for measuring blades. It enables automatic loading and unloading of multiple blades and automated 3D measurement. Based on the scanned results, the parameters such as chord length, blade thickness, and blade edge R can be automatically analyzed to determine whether the blades are qualified.

Blade Size:The size of measured blade ranges from30mm-300mm in height.

System Composition:The system mainly consists of three modules: manual clamping, robot automatic loading and unloading, and blue light automatic 3D scanning.

Measurement Accuracy:Using a high-precision 3D sensor of PowerScan 12M, with a camera resolution of up to 1200 pixels, the highest single measurement accuracy can reach to 0.008mm.

Inspection Speed:The inspection time is 2-4 min/ piece, and 8 blades can be detected in each batch.

Last:

Next:Solutions

-

Pre-sales:sales@vision3d.cnAfter-sales:aftersales@vision3d.cn

-

Pre-sales: 189 7166 9261After-sales:189 7166 8135

-

Consultation