Welcome to Vista 3D Technology Co., Ltd.!

Mobile

Application cases

From:惟景三维 Author:Vision3D

222023.09

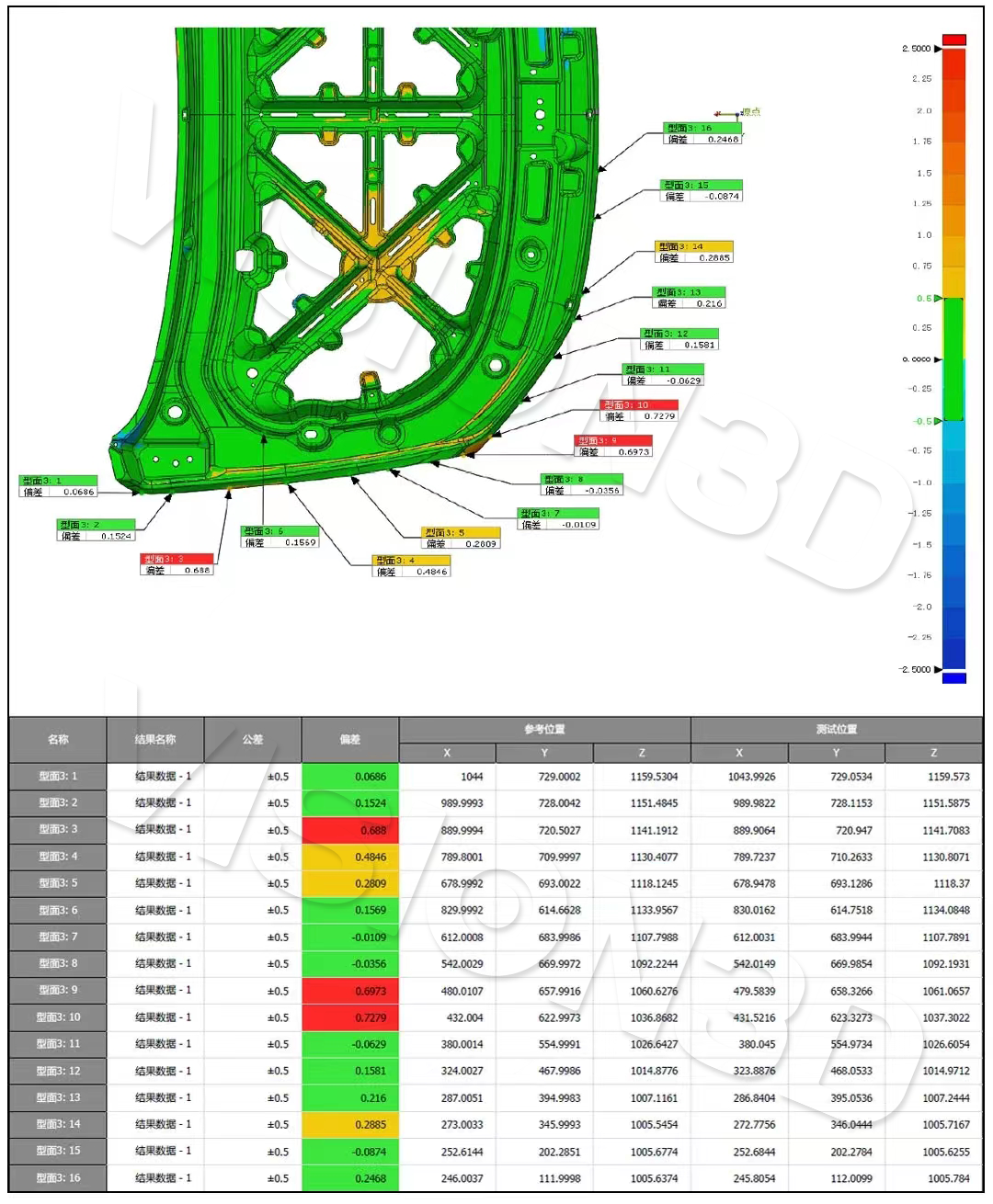

Automated 3D Measurement and Precision Inspection for Inner Panels of Automotive Engine Hoods

The complex structure and high forming precision requirements of automotive bodies and panels pose challenges for traditional measurement methods such as gauges, calipers, and coordinate measuring machines (CMMs). These methods often suffer from issues like limited coverage, low data density, and inefficiency.

The AutoScan series of devices enable in-line or on-line automated 3D measurement, catering to tasks such as first and last piece inspection, frequent sampling, and full-inspection in batch production. This greatly improves measurement efficiency, accuracy, and automation level for automotive bodies and panels.

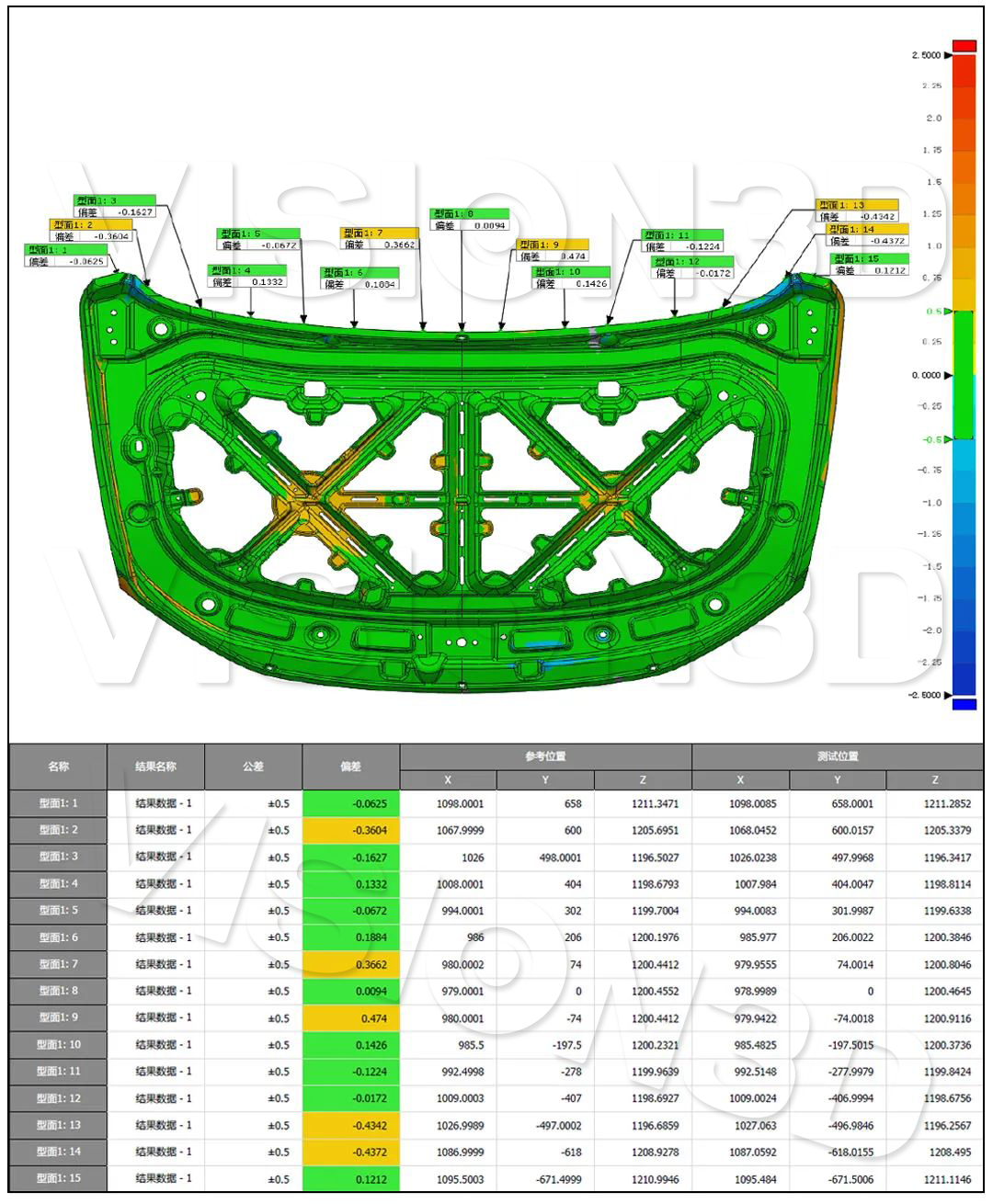

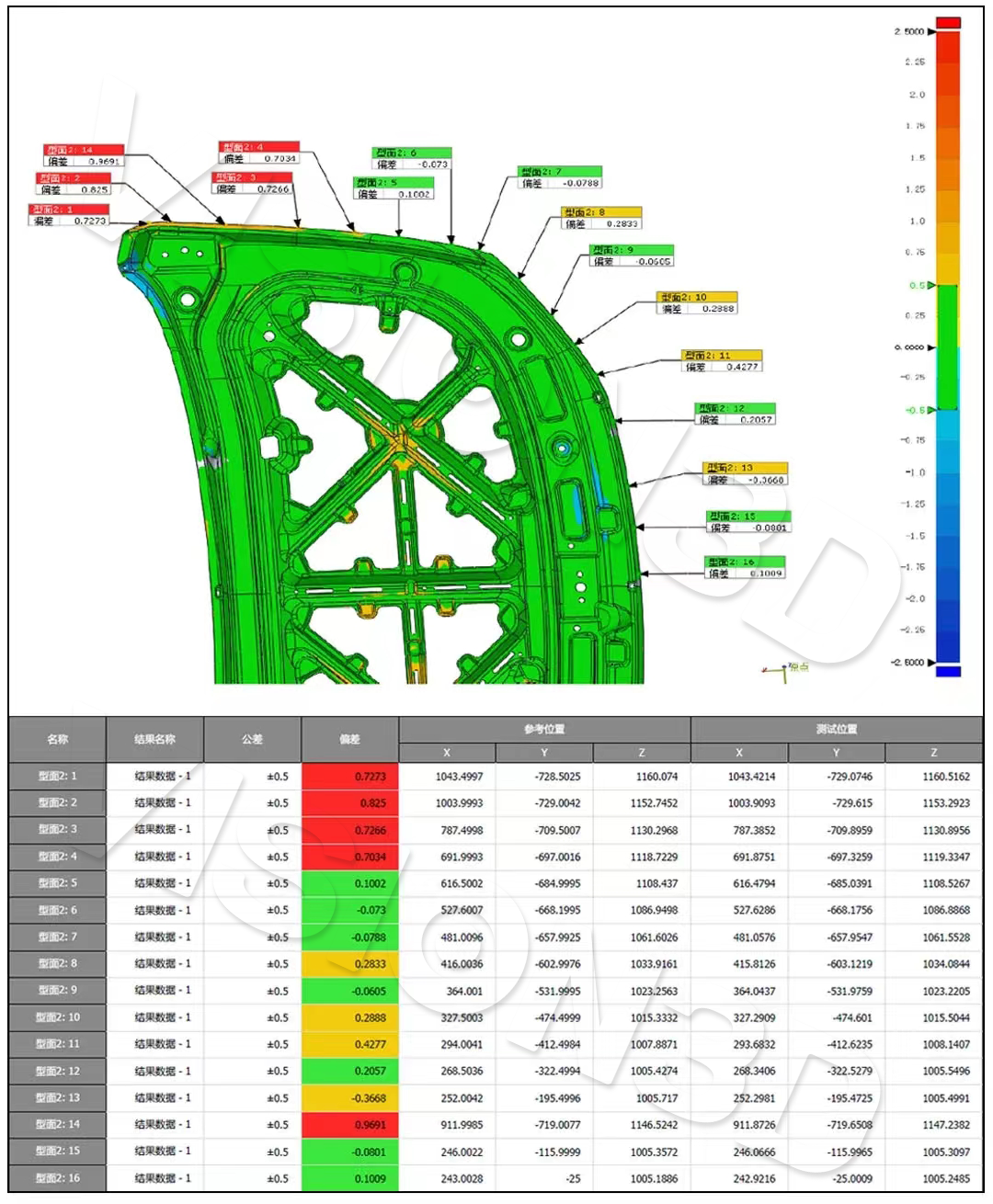

AutoScan 1000 is used for high-frequent sampling inspection of engine hood inner panel. With a part size of 1×1.6 meters, the accuracy is better than 0.05mm, and each part can be measured in two and a half minutes, meeting production cycle requirements. After scanning, customized reports are automatically generated, including key data such as hole positions, diameters, and surface deviations.

—Unmarked Automatic Stitching Technolog

Without the need for markers, it saves labor on tasks of pasting and cleaning. The entire measurement process is automated, improving measurement efficiency and automation level.

—Image-based Hole Position Recognition Technolog

It allows for rapid identification of circular holes on the part’s surface. In addition to detecting the contour dimensions of the part, it can also provide information of hole position errors, offering versatile inspection capabilities.

customized inspection report

Last:Application cases

Next:Solutions

-

Pre-sales:sales@vision3d.cnAfter-sales:aftersales@vision3d.cn

-

Pre-sales: 189 7166 9261After-sales:189 7166 8135

-

Consultation